What is Pultrusion?

What is Pultrusion?

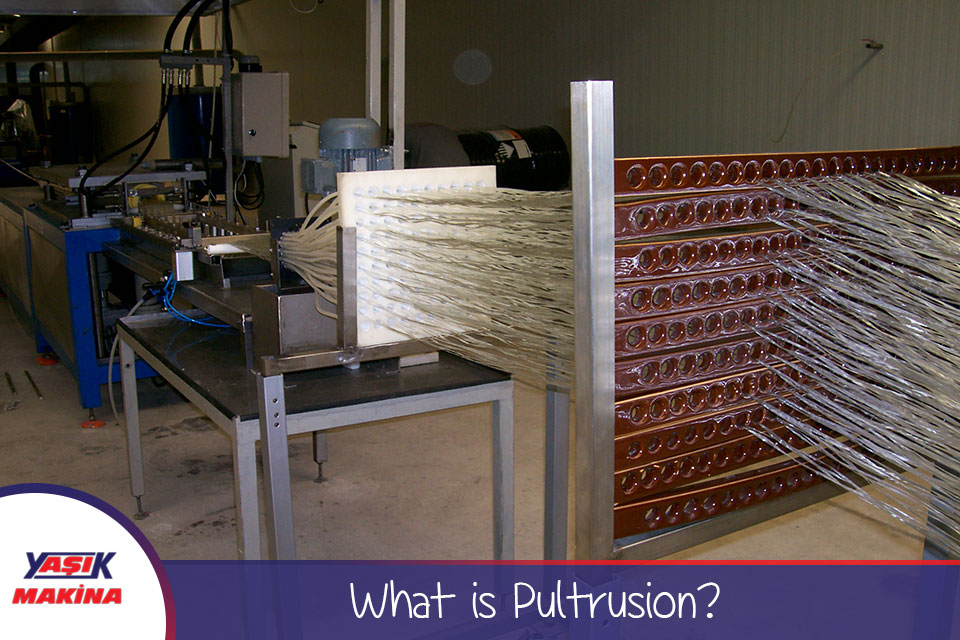

Pultrusion is a production process for producing reinforced polymer structural shapes in continuous lengths having a constant cross-section. The process involves the extraction of raw materials, a liquid resin mixture and reinforcing glass fibers along a heated steel forming die using a continuous drawing apparatus.

What is Fiberglass Reinforced Polymer?

Fiberglass Reinforced Polymer (FRP) is often referred to as "fiberglass". The "fiberglass" used in this context is a composite consisting of a polymer resin matrix reinforced with embedded glass fibers. The strength of a fiberglass part is determined mainly by the type, direction, quantity and location of the glass fibers in the composite.

Properties of Fiberglass Composites

High power

Stronger than structural steel. Structures, walkways, platforms etc. Using for.

Light

Fiberglass composite products are about 75-80% less than steel and 30% less than aluminum. This means lower shipping costs, easier installation and less weight in structural designs.

Corrosion resistance

Fiberglass does not rot and is not resistant to insects and a wide range of corrosive environments. FRP composites are successfully used in indoor and outdoor applications in hotels, restaurants, chemical plants, water and wastewater treatment plants and many other corrosive environments.

Low conductivity

Fiberglass, which is an excellent insulator, has low thermal and electrical conductivity and is thus a popular choice in electrical applications.

Electromagnetic Transparency

Fiberglass is transparent to radio waves, microwaves and other electromagnetic frequencies. Thanks to this feature, composite products are regularly used in cellular applications.

Benefits of Fiberglass

Reduced Maintenance Costs

Fiberglass corrosion resistance means that the need for routine painting and repair is virtually eliminated. For this reason, life cycle costs are usually significantly lower than traditional materials.

Heavy Lift or No Source

Fiberglass is lightweight and may require less equipment, workers and time for installation. In addition, fiberglass can be manufactured with standard carpentry tools (using carbide or diamond blades). This reduces the risk of on-site injury and downtime associated with conventional materials and installation equipment.

Aesthetic Resistant

Fiberglass products are based on weather and intensive use, providing long lasting beauty. Once installed, the products require extremely little maintenance.

Safer for employees

Fiberglass products are not electrically conductive and can be manufactured with non-slip surfaces to provide a safe working environment for workers.